Overview

Designed for use by a large utilities company in Germany, the plant produces hydrogen gas from water and mixes this with natural gas. This mixture is injected into the German gas grid for use by consumers.

ITI Group designed and installed a control and protection system that can be run autonomously while also monitoring safety critical data. The supervisory system provides a local and remote visualisation of the plant and key processes and alerts the utility company to any system anomalies. The control and protection system ensures a safe working environment for operators and provides an instant notification of alarms to key personnel. This enables the gas supplier to identify issues which could disrupt supply and improve customer service.

Fully integrated solution

TUV/CompEx certified engineering solution

Dedicated ITI team

Familiarity with the site and systems helped deliver the project on time and on budget

Safety First

Adhering to the clients’ functional safety and hazardous area assessments, the ITI solution employed Siemens fail-safe S7-300 F-rated PLC controllers and safety I/O modules with suitable SIL protection to meet a number of client defined Safety Instrumented Functions (SIFs).

Pepprl and Fuchs intrinsically safe barriers were used to provide a safe interface from the hazardous area signals which originated in Zone IIC T4.

A Siemens TP1500 15” Touchscreen running WinCC provides the operator with a holistic view of all processes.

Siemens GSM and GPRS modules provide access for remote monitoring of the process from the site in Germany.

All the equipment was housed within a number of control panels which were designed, built and tested in-house by ITI, including ATEX-certified panels.

Control hardware specification, design and build for numerous control panels

Compliance with Ex/ATEX requirements

Software specification, design and test, including safety and automated process area sequencing

Human Machine Interface (HMI)

Electronic data and record storage

Protection system to BS EN IEC61511/61508

Installation of the control panels into the containerised system, including all electrical and instrumentation connections and CompEx certification

Full functional testing at the client’s premises

On site assistance

Flexible Approach

ITI Group’s extensive experience in design of process control and safety systems reduced design and delivery timescales offering the customer an efficient path from concept to commission. Our team of multi-disciplined engineers were dedicated to the project throughout the development and installation of the system, offering onsite support and ensuring consistent delivery of knowledge and a familiar point of contact for the project team. ITI Group’s flexible approach and familiarity with the site, plant architecture and systems helped deliver the project on time and on budget.

How we’ve helped other businesses like yours

Sellafield FGMSP Digital Twin and 3D Planning Tool

ITI Group worked with Sellafield to create a digital twin of the FGMSP, plus an integrated 3D interactive planning tool, to determine the most effective sequences for waste removal based on a myriad of interdependencies.

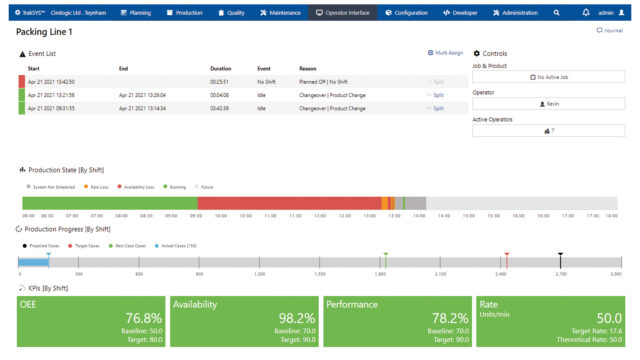

Purity Soft Drinks Achieved Efficiency Improvements of 20%

Leading soft drinks manufacturer achieves OEE efficiency gains and data insight to drive continuous improvement from real-time OEE platform.

Spirit Energy Digital Transformation

After just one year of collaborating with ITI Group on their Digital Transformation programme, Spirit Energy are already seeing the benefits of a properly managed data solution.

How can we help you?