Regulatory Requirements

The recording of control rod drop times is a regulatory requirement of the nuclear site license. To overcome the spares issues with obsolete equipment, ITI Group developed a Rod Drop Monitoring system using commercially off-the-shelf hardware and software. The solution can be easily adapted to the requirements of any nuclear power station, and has a proven install base.

SYSTEM BENEFITS

Automatic data processing:

The previous system involved laborious manual intervention to process & print the data charts. All data processing & chart printing is fully automated in the new system.

Calibration facility:

The system includes a calibration spreadsheet HMI to allow operators to calibrate the rod height data against actual rod height (conversion of pulse inputs into analogue rod height).

Resolution:

The system provides increased resolution & extended windows for the data charts. This enhances the data quality for ‘post trip’ analysis work.

Chart Display:

multi-line detailed charts showing 2secs before trip and 28secs afterwards.

Security:

User access is based on an ‘administrator controlled’ user privileges set-up.

File management and archiving facility:

offering user-friendly off-line storage of trip & calibration data.

Real-time rod height display & slack switch status

Automatic collection of ‘reactor trip’ data.

Data window requirements:

- Data window to start at 2 sec. pre trip condition.

- Data window to extend for 28 sec. post trip condition

- Data collection to include all 121 rods.

- Data resolution: 20 msec.

Data visualised through chart display & printouts:

rod height versus time.

System calculates intermediate values

Alarm system

including reactor trip, power supply failure & system health status

How we’ve helped other businesses like yours

Sellafield FGMSP Digital Twin and 3D Planning Tool

ITI Group worked with Sellafield to create a digital twin of the FGMSP, plus an integrated 3D interactive planning tool, to determine the most effective sequences for waste removal based on a myriad of interdependencies.

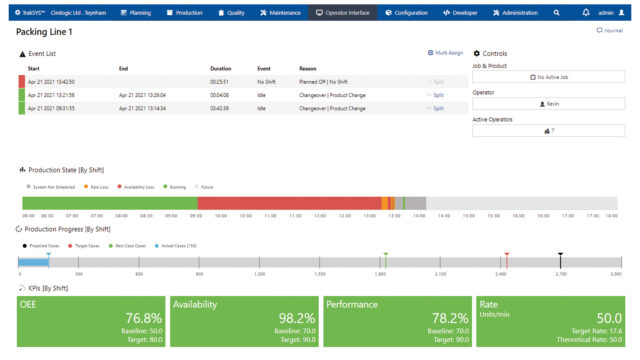

Purity Soft Drinks Achieved Efficiency Improvements of 20%

Leading soft drinks manufacturer achieves OEE efficiency gains and data insight to drive continuous improvement from real-time OEE platform.

Spirit Energy Digital Transformation

After just one year of collaborating with ITI Group on their Digital Transformation programme, Spirit Energy are already seeing the benefits of a properly managed data solution.

How can we help you?