The Brief

The programme has improved reliability and integrity as well as minimising production downtime of 2,800 pieces of major rotating equipment including turbines, compressors and safety critical equipment.

ITI Group’s Real-time Information System (RtIS) visualises trends related to vibration, temperature and other vital data, enabling the prediction and prevention of potential equipment failures. The programme saved Repsol Sinopec an estimated $9m in downtime costs in the first year, for an outlay of just $1m.

Repsol Sinopec initiated its Rotating Equipment Excellence Programme in order to assess the overall performance of all its rotating equipment, improve examination of asset utilisation and ultimately extend the life of existing infrastructure.

Previously, much of Repsol Sinopec’s equipment was monitored using a number of third-party systems, with each focussed on a single type of equipment, and each having their own requirements for instrumentation as well as varying licensing costs. Although the operator had been using OSIsoft’s PI System (now the AVEVA PI System) for management of real-time data and events, the number of different monitoring software packages in use meant inconsistency in the information being gathered and delivered from the wide range of rotating equipment.

Repsol Sinopec’s rotating equipment specialists carried out extensive analysis to identify all their highest risk equipment: the oldest items that would cause the most severe downtime costs and those which had monitoring systems providing the most basic information.

The oil and gas operator then called upon the expertise of ITI Group’s Realtime Information specialists to collect all the data into a centralised plant information system and visualise the key characteristics to enable optimal business decisions to be made.

2,800 pieces of equipment monitored

24 days downtime saved on two pieces of equipment

$9m lost revenue avoided on two pieces of equipment

Sharing of information improved

Reduced third-party licensing costs

Reducing Downtime

Repsol Sinopec saw ROI on the project within the first few months. The system enabled operators to take preventative actions that avoided or minimised downtime:

- The application detected a differential pressure that was well beyond the operational limit and alerted the relevant personnel to the situation. Without such an alert, filter damage would have caused an estimated 14 days of downtime with consequent deferment resulting in $6milllion of lost revenue at a $40/bbl level.

- By monitoring the temperature of a high seal oil tank, onshore users were altered to and able to resolve a reading significantly above the average temperature. Seal failure could have caused ten days lost production equating to lost revenue of around $3million.

Further Business Benefits

The use of a single consistent automated monitoring system in Repsol Sinopec’s upstream operations streamlines the integration of new or upgraded equipment into the application.

The historical benefits for similar equipment can be analysed to build a business case for new assets, which can then be easily integrated into an enhanced maintenance management regime.

The software has also improved internal collaboration, particularly between onshore and offshore teams. With all staff using one system, information is easily shared and acted upon by a range of technical and nontechnical users.

The Solution

Working collaboratively with the client, ITI Group developed an application based on the familiar PI System infrastructure to monitor critical equipment throughout their upstream operations.

The evolutionary application provides a central monitoring system across the client’s entire network, presenting all information in a consistent manner, promoting ease of use and reducing third-party licensing costs.

Equipment monitored by the application is shown on a standard display providing information on process values and equipment operating points. Summary displays allow non-technical staff to focus on individual assets and interpret key data, with more detailed data readily accessible for those that require it. The application was developed to continuously monitor live values against alarm limits and thresholds, with notifications provided instantaneously via email. Prior to the development of the software by ITI Group, this data had to be monitored and analysed manually.

Development of the programme has brought real value to the way Repsol Sinopec maintains its critical rotating equipment. The system has reduced the lead time on the detection of performance and integrity issues, allowing for swifter action in resolving operational problems. The application’s history functions allow users to make informed proactive decisions to minimise downtime and prevent production or mechanical issues.

The system is open to development as Repsol Sinopec’s needs change and ITI Group has since extended its use to enable deployment for other customers: improving reliability and integrity of equipment through effective monitoring and maintenance.

How we’ve helped other businesses like yours

Sellafield FGMSP Digital Twin and 3D Planning Tool

ITI Group worked with Sellafield to create a digital twin of the FGMSP, plus an integrated 3D interactive planning tool, to determine the most effective sequences for waste removal based on a myriad of interdependencies.

Purity Soft Drinks Achieved Efficiency Improvements of 20%

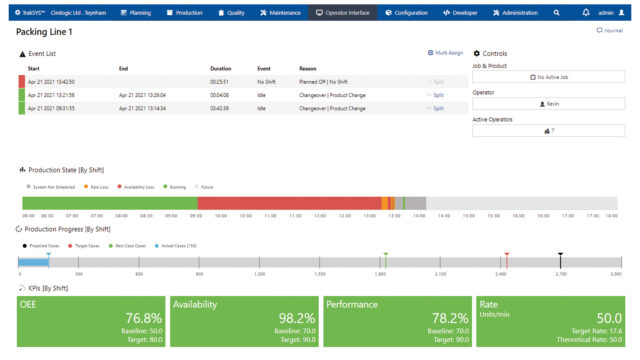

Leading soft drinks manufacturer achieves OEE efficiency gains and data insight to drive continuous improvement from real-time OEE platform.

Spirit Energy Digital Transformation

After just one year of collaborating with ITI Group on their Digital Transformation programme, Spirit Energy are already seeing the benefits of a properly managed data solution.

How can we help you?