As part of a Liquor Activity Reduction (LAR) project aimed at improving the overall safety and reducing risk at the Magnox Swarf Storage Silo (MSSS), ITI Group was contracted by Sellafield’s contractor Nuvia to provide Safety and Control Systems to monitor and control the active water in the aging storage facility.

ITI Group designed, built, commissioned and factory tested, to Sellafield’s exacting requirements, an Independent Hardwired Safety System and separate Control System which strengthened the functionality of the plant, improved its longevity, and supported the Silo Emptying Plant (SEP) operations, ultimately enabling the decommissioning and eventual demolition of the legacy building, for a safer future.

Strengthened Safety

ITI Group designed, built, commissioned and factory tested, to Sellafield’s exacting requirements, an Independent Hardwired Safety System and separate Control System which strengthened the functionality of the plant, improved its longevity, and supported the Silo Emptying Plant (SEP) operations, ultimately enabling the decommissioning and eventual demolition of the legacy building, for a safer future.

The MSSS building at Sellafield stores a substantial legacy of radioactive waste underwater in quiescent conditions, but cannot do so indefinitely. ITI Group’s bespoke independent hardwired safety system monitors the liquor levels inside the compartments, instantly reacting to put the plant into a predefined safe state should a trip or interlock be activated, in order to fulfil the immediate requirement of mitigating risks associated with legacy waste storage.

Separate safety and control systems that fully integrate with plant operations

Strengthened functionality and reduced risk

Designed and built to exacting requirements

Facilitating client’s long-term decommissioning mission

System Experience and Transformation

ITI Group had previously undertaken a First Extension Liquor Activity Reduction project for the client, who then extended the scope to meet further needs for the original building and to enhance the safety and performance of the plant. This experience, combined with a proven track record of projects at Sellafield, gave the client the confidence that ITI Group would deliver the in-depth design justification, design analysis and panel construction to Sellafield’s exacting standards.

ITI Group then designed, manufactured, tested and supplied replacement panels and a hardwired trip system to retain all existing functionality, in addition to providing the new functionality and additional components to enable the termination of the previous panels.

“We always know we can rely on ITI Group to deliver.”

“They once again provided a solution that fulfils all of Sellafield’s requirements, to our specific time and budget constraints, which is imperative to achieving successful collaborative project delivery.”

Steve Miller – Operations Director, EPC and Programmes, Nuvia Limited

Complete Control

ITI Group’s control solution for the one-of-a-kind facility replicates all the existing functionality, then builds on that to provide further full control of the original building and first extension parts of MSSS.

The bespoke control system performs all the liquor movements including washdown, transfers, pumping and maintenance sequences, and provides operators with a bespoke human-machine interface for real time information connected to the client’s data acquisition monitoring system.

Supporting a Safer Future

Fully future-proofed, the systems are open to reconfiguration to allow second stage waste removals, upon completion of this first stage deployment.

The systems work synonymously with the silo emptying plant retrieval machines to facilitate liquor level management and eventually facilitate the complete removal, repackaging and long-term storage of the radioactive waste. This in turn will allow the eventual demolition of the aging building, allowing Sellafield to complete their mission of fully decommissioning the entire radioactive legacy, for a safer future.

How we’ve helped other businesses like yours

Sellafield FGMSP Digital Twin and 3D Planning Tool

ITI Group worked with Sellafield to create a digital twin of the FGMSP, plus an integrated 3D interactive planning tool, to determine the most effective sequences for waste removal based on a myriad of interdependencies.

Purity Soft Drinks Achieved Efficiency Improvements of 20%

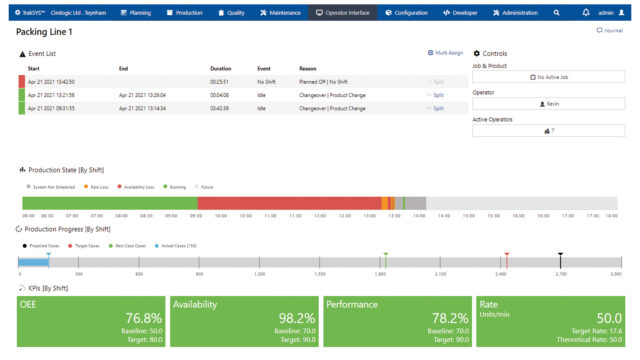

Leading soft drinks manufacturer achieves OEE efficiency gains and data insight to drive continuous improvement from real-time OEE platform.

Spirit Energy Digital Transformation

After just one year of collaborating with ITI Group on their Digital Transformation programme, Spirit Energy are already seeing the benefits of a properly managed data solution.

How can we help you?