Robust, reliable and integrated

This major new build mechanical handling facility will be used for supplementary storage, inspection, loading, decontamination and maintenance operations – supporting waste retrieval operations from legacy silos, as waste is moved from the Magnox Swarf Storage Silo (MSSS) and Pile Fuel Cladding Silo (PFCS) into safe containment.

This process requires a robust, reliable and integrated control system across multiple plant areas, and related processes.

Our software and hardware systems must help deliver a safe, secure environment – where maintenance can be carried out on the machinery doing the most important job in UK nuclear decommissioning.

OUR IMPACT

Fit for the future

A complex multi-subsystem control solution for a new facility

Network performance and cyber-security monitoring and management

Delivery of extensive systems training to Sellafield personnel

Future development capability

Exemplary health and safety record achieved with zero lost time accidents

Project achieved an NDA ‘excellent’ milestone for compliance with strict standards and legislation

APM ‘Project of the Year Award’ for Engineering, Construction and Infrastructure

COLLABORATION AND INTEGRATION

Working Together

We were part of a fully-integrated and energised team operating across co-located offices in (Cheshire), our own facilities in South Yorkshire, and the Sellafield site.

After overseeing manufacture and factory acceptance testing at our modern manufacturing facility in South Yorkshire, we focused our resources on the SMF Delivery Team’s Integrated Works Test Facility.

We installed and supported testing of the system in conjunction with various plant packages, before shipment to the Sellafield site. This included the project management of sub-contracted specialist seal interspace test panels.

OUR LEGACY

A cleaner future for nuclear power

We’ve helped the nuclear site to move into a 100-year programme of environmental regeneration.

Our systems will aid the speed of decommissioning old facilities and are trusted to improve the management, safe retrieval and storage of the most hazardous waste in the UK.

- For generations to come, the site will provide employment opportunities in West Cumbria, the Warrington area and the wider industry.

- The systems and training we delivered to Sellafield, will also make sure the site has the capacity to adapt to the demands of the future – as new practices, regulations or technology drive change over time.

- We also continue to support the installation and commissioning of the SMF systems within the new facility on site.

What we did

Network Control & Operations

We provided an overall control system incorporating a series of PLC/HMI subsystems together with a Plant-Wide Alarm System. This provides local and remote control of all the operations inside the SMF.

- Flask loading and maintenance

- Package collection

- Package and shield door operation

- Import and export of components inside package skips

- Decontamination, wash-down and effluence collection and sentencing

- Bogie maintenance

- In addition, we provided:

- A hardwired safety interlock system

- An Equipment Tracking System using hand-held bar code scanner devices and commercial off the shelf (COTS) software

- A full Network Monitoring and Management System

- A comprehensive Offline Development and Test System

Performance & Safety

- We delivered over 40 control panel cubicles across nine subsystems. These incorporated Programmable Logic Controllers (PLCs) and Variable Speed Drives (VSDs) to control the shield doors, import bogie, gamma gate, skip bogie, package hoist, mast hoist and door removal machine.

- A Supervisory Control and Data Acquisition (SCADA) System monitors, analyses and controls plant processes and performance.

- Numerous Human Machine Interface (HMI) displays monitor and provide local control for individual areas of the plant.

- The Network Monitoring and Management System uses powerful monitoring, lockdown and whitelisting software packages.

- This gives the Sellafield the capability to diagnose interruptions, faults, intrusions, undesired traffic. It also allows them to control the launch and use of all active applications.

- A Management Information System integrates the control solution with the Plant-Wide Alarm System and provides data from across the whole of the SMF.

- The system’s reporting software logs, displays and reports alarm and process data to alert operators to conditions, including alarm states from radiological monitors.

How we’ve helped other businesses like yours

Sellafield FGMSP Digital Twin and 3D Planning Tool

ITI Group worked with Sellafield to create a digital twin of the FGMSP, plus an integrated 3D interactive planning tool, to determine the most effective sequences for waste removal based on a myriad of interdependencies.

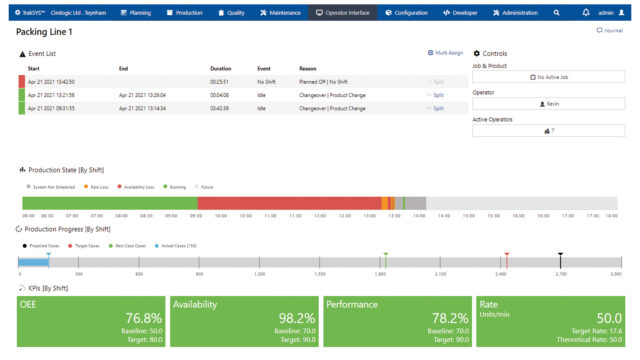

Purity Soft Drinks Achieved Efficiency Improvements of 20%

Leading soft drinks manufacturer achieves OEE efficiency gains and data insight to drive continuous improvement from real-time OEE platform.

Spirit Energy Digital Transformation

After just one year of collaborating with ITI Group on their Digital Transformation programme, Spirit Energy are already seeing the benefits of a properly managed data solution.

How can we help you?