Overview

Built in 1952 to supply electricity to the island community, the Storr Lochs scheme is now an integral part of the national electricity supply network, producing an average of 8 Giga Watt hours of electricity per year.

As part of an overhaul of Storr Lochs by SSE, ITI completed a full upgrade and replacement of the low voltage distribution, protection and control equipment, providing a modern robust platform to support the station’s operation into the foreseeable future.

“The project was completed to a high technical standard”

“We chose Servelec Controls because of their software know-how and technical expertise in control system integration. The project was completed to a high technical standard and we’re confident that the new system will support the plant to efficiently provide energy to the Grid for the next 25 years.”

Ian Heywood – SSE

The Systems

As the main subcontractor, ITI undertook all of the design, installation and commissioning for all the panels, cabling and software required to upgrade the Storr Lochs systems.

The station houses two turbine generator sets (units), each requiring identical control, power, protection, Main Inlet Valve (MIV) and Automatic Voltage Regulator (AVR) panels. Each unit is controlled by its own Programmable Logic Controller (PLC) and a third controls the station ancillary services. Further panels operate these ancillary services, which include the station battery system, remote telemetry, building ventilation and extraction, winch house, station service change-over, and communications connections between the station, winch house and valve house.

ITI then supplied all spares, cabling, junction boxes and software to complete the installation. ITI programmed and integrated the various hardware and software applications from a variety of different manufacturers, including Allen Bradley, Rockwell, SEL and Voith as specified by SSE, into a single architecture, then carried out all the installation, testing and commissioning to provide a safe, reliable control system to run the Storr Lochs scheme for years to come.

Enhanced Solution

ITI has worked in partnership with SSE to successfully deliver numerous projects. This joint approach has enabled the integration of best practice with operating experience from previous projects to develop and improve project delivery. The integrated electrical and control system at Storr Lochs will benefit from a number of upgraded features:

Automated station control based on reservoir level

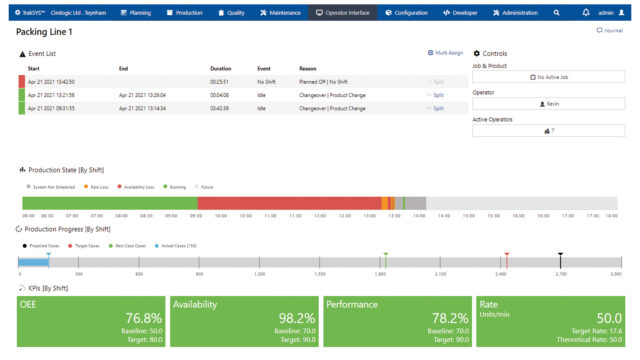

Visual indication from the HMIs (Human Machine Interface)

Improved Alarm & Event Monitoring & Data Logging

Robust remote links back to the central control room at Perth

Benefits

The new control system will provide a reliable, fully automated and user-friendly system to support electricity generation from Storr Lochs for the next 25 years. Designed to standards consistent with other facility upgrade projects across the SSE fleet, it will provide improved control, a commonality of spares and reduce the amount of operator training required.

Ian Heywood Programmes Lead Engineer (C&I) at SSE said: “We chose ITI because of their software know-how and technical expertise in control system integration. The project was completed to a high technical standard and we’re confident that the new system will support the plant to efficiently provide energy to the Grid for the next 25 years.”

How we’ve helped other businesses like yours

Sellafield FGMSP Digital Twin and 3D Planning Tool

ITI Group worked with Sellafield to create a digital twin of the FGMSP, plus an integrated 3D interactive planning tool, to determine the most effective sequences for waste removal based on a myriad of interdependencies.

Purity Soft Drinks Achieved Efficiency Improvements of 20%

Leading soft drinks manufacturer achieves OEE efficiency gains and data insight to drive continuous improvement from real-time OEE platform.

Spirit Energy Digital Transformation

After just one year of collaborating with ITI Group on their Digital Transformation programme, Spirit Energy are already seeing the benefits of a properly managed data solution.

How can we help you?