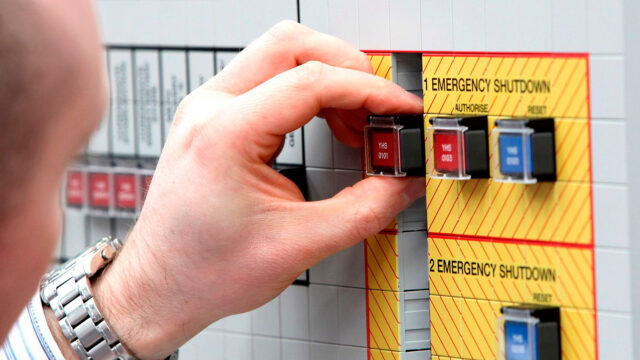

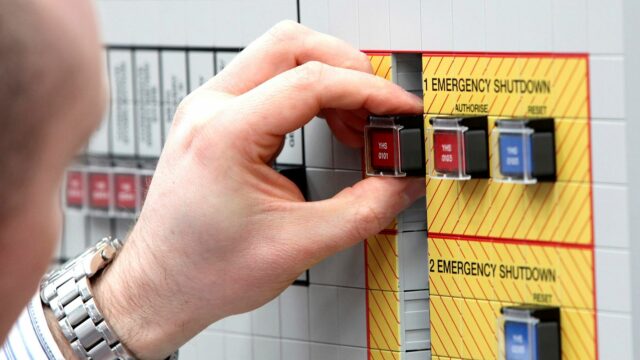

Comprehensive control, protecting your operations

A distributed control system (DCS) coordinates multiple automated control elements, providing an overview of many production elements on multiple sites – from a single system.

Each process can then have its own dedicated control system, usually PLC based, to run its own operation. This can reduce development and installation costs, as well as provide a level of protection.

Our Distributed Control Systems provide a cost-effective control system solution when you’re also looking to minimise risk by separating each process in your operation.

We’re the sharp minds, and safe hands

Our highly qualified engineers have extensive, proven experience of installing safe, reliable, scalable control systems for clients across a wide range of critical industries.

Our people are focused on the vital details at the heart of critical operations, and are trusted to deliver systems that protect them.

Future-focused, to enhance your evolution

We can seamlessly integrate a new distributed control system into your operations, incorporating many of the major manufacturers’ products.

We deliver systems with a focus on futureproofing, so that your capability can be adapted alongside your changing operations, as your business evolves over time.

More in Safety and Control

View our Case Studies