Combining constant protection, and real-time optimisation

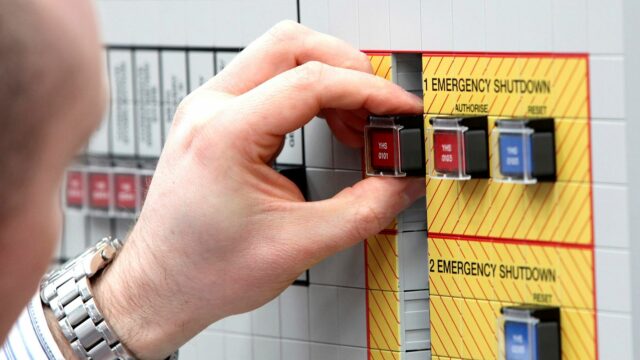

Process control systems continuously monitor industrial assets, reading operational variables such as temperature or pressure levels, and applying algorithms to determine whether they are running at optimum and/or safe levels.

With the right architecture, this data can then be used to make the appropriate adjustments in real-time in order to maintain operation within predetermined safety and production parameters.

Trusted teams, engineering greater efficiency

We have extensive experience with automated systems, and an in depth understanding of all the markets we serve. They rely on our people to deliver innovative, robust systems, and enhance their capabilities.

Our team will work with you to understand your operations and specific requirements in order to create a solution that will help you optimise your operations, achieve production efficiency, and enhance the safety of your plant and personnel.

Achieve new levels of consistency, economy and safety

We can create or upgrade your process control systems to automate the fine-tuning of your operational processes, enabling you to achieve a level of production consistency, economy and safety that would not be possible purely by manual control.

Our process control systems will help ensure that even your most complex processes are predictable, stable and consistently operating at your target level of performance.

More in Safety and Control

View our Case Studies