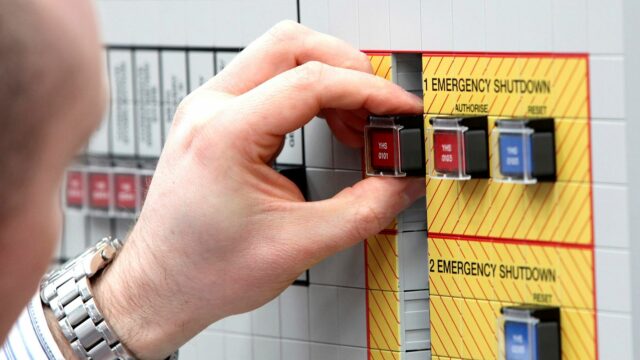

Maximise the visibility of plant equipment to improve all areas of operations

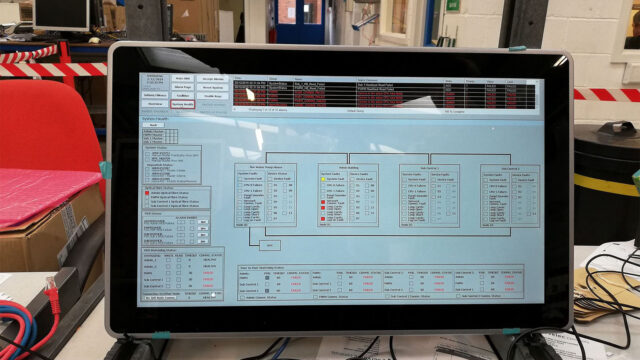

Organisations are using SCADA, HMI, and IIoT systems to improve operational efficiency, enhance customer experience, support digital transformation initiatives, and meet ESG (Environmental, Social and Governance) targets.

Does your SCADA system provide the flexibility and innovation needed to stay one step ahead of the competition? Does it enable the connectivity of assets and provide real-time data intelligence to enhance the operations and processes that it serves?

SCADA is a game-changer for many modern industrial operations, opening the door to address some of the typical business and operational challenges:

- Increasing production capacity

- Enabling full visibility of enterprise assets

- Reducing New Product Introduction (NPI) Time

- Ensuring maximum availability of machinery and equipment

- Achieving On-Time In-Full Delivery

- Achieving carbon reduction and sustainability goals

- Meeting regulatory compliance and quality standards

- Reducing the cost of goods

Beyond technology

It’s not just about the technology; people and processes must be considered too, and that’s where our business-led digital strategists at ITI Consulting come in. With the expertise of our ITI Consulting team and utilising the unique RAISE™ methodology, ITI Group supports clients in achieving their business goals with effective, appropriate digital solutions, realising maximum business value. We are committed to ensuring the success of our clients Digital Transformation projects.

Meet our ITI Consulting leadership teamYour technology partner for Digital Transformation

ITI Group has a wealth of experience in industrial automation, process control, and SCADA, HMI and IIoT system integration for the Nuclear, Energy and Manufacturing sectors. We ensure that your SCADA system is integrated seamlessly with your existing processes and systems to maximise the visibility of plant equipment to help improve all areas of your industrial operations.

We are recognised systems integrators for the following historian and MIS solutions

More in Safety and Control

View our Case Studies